"Shaft down" is the preferred orientation for mounting a Lift Support. An optimum design would permit the support to be oriented shaft down through its entire actuation. If this is not possible then try to install so that the shaft is pointing downward in the Closed Position.

There are several reasons for this:

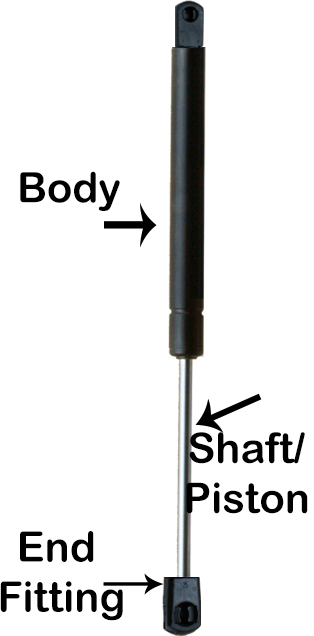

In order to achieve the damping or "cushion" at the end of the Lift Support's stroke, the piston assembly inside of the Lift Support must travel through oil at the end of the stroke. "Shaft down" orientation ensures that the oil is in the proper location for damping to occur.

"Shaft down" orientation ensures that the shaft and sealing components are lubricated with every stroke of the Lift Support. This reduces seal wear and helps to inhibit corrosion.

Depending on the application, "shaft down" orientation may reduce the rate of gas permeation through the seal, which increases the useable life of the Lift Support.

Some Reasons why not to change the orientation of the support.

1) Vehicles with power openers must be installed in the same direction as they came from the factory. Sensors on the door are adjusted to work in the way they were programmed. Installing in the opposite direction can cause them not to work properly.

2) Some model of vehicles do not allow space for the cylinder to be reversed and this will cause a binding when the door or window closes. An example of this is the Ford Excursion Rear Window (or liftgate)

Please keep in mind the more often that a cylinder is used the longer it will last. Sitting dormant for any period allows the shaft to bind to the seal and eventually tear. If the application must remain dormant then when opening after sitting lift very slowly.